4 Stepping Stones to Sustainability for New Construction Firms

The construction industry has a well-deserved reputation for being an environmental polluter. It has gotten away with ungreen practices because the other sectors are just as dirty, if not more. However, climate change has made the world less tolerant of environmentally unsound organizations. Governments have joined the sustainability movement, so the writing is on the wall for maladaptive enterprises.

Many firms are slow to adopt greener practices, but the influx of startups can accelerate the sector’s sustainability transformation. New design-build firms, general contracting businesses, and subcontractors are better positioned to embrace eco-friendly initiatives.

The corporate culture is still a blank canvas, so start fresh with these four tips.

- Go Digital

Technological adoption and sustainability go hand in hand. Outdated methods and crude tools limit your ability to overcome your blind spots and find opportunities to operate more sustainably. Investing in digital technologies is necessary to address your pain points and streamline your processes.

Which innovations should you prioritize? There are numerous excellent candidates:

- Mobile devices and messaging tools can harness cloud computing’s potential to promote remote resource access and foster interconnectedness. The interplay between these technologies will break down the usual communication barriers, making it easy to keep everybody on the same page.

- Computer-aided design, building information modeling, and construction management programs streamline processes. They have unique functions but digitize data so you can review information more granularly. Analytics programs can reveal insights to solve problems that harm the environment, like surplus inventory and rework.

- LiDAR and camera-equipped drones, wearable Internet of Things devices, and telematics systems can collect data on almost anything. They can help you precisely and accurately scan the landscape to minimize disturbance on existing ecosystems, quantify worker performance to identify and correct wasteful habits and keep tabs on equipment usage.

- Bots automate tedious tasks, allowing you to conduct construction work more efficiently. Robotic arm 3D printers and bricklayers can help you complete projects faster and decrease material waste.

Construction has been slow to innovate primarily due to employee hesitance. Feeling intimidated by innovative solutions and receiving inadequate technical support are some of the usual baggage crews carry. Budget for training and continuous learning, as technologically savvy workers feel comfortable with innovations and can maximize their tools to run your business more sustainably.

- Be Circular

Circularity promotes using renewable, reclaimed or recycled materials, reusing or repurposing items, recovering salvageable materials, and designing structures with easily recoverable components. Such practices aim to leave the remaining virgin resources untouched because logging, mining and quarrying have considerable environmental consequences. These extraction methods destroy natural habitats, displace wildlife, eradicate biodiversity, pollute soil, water and air, and reduce natural carbon sinks.

Considering the planet’s finite resources, the construction industry has to switch from the linear to the circular model sooner rather than later. Otherwise, the sector will face crippling supply chain disruptions, which can result in project delays and loss of profits. How do you join the circular economy?

- Buy reclaimed, recycled and repurposed construction supplies: Try doing so whenever you can to help conserve virgin resources.

- Choose vendors carefully: Circular suppliers engaging in unethical practices practice greenwashing, not sustainability. Exercise due diligence to ensure your supply chain partners are as green as they claim to be to avoid enriching environmentally damaging businesses.

- Select used equipment over new products: Purchasing pre-owned tools, machines and vehicles is sustainable because they’re already around. Ordering brand-new assets incentivizes manufacturers to build more products, potentially using newly extracted raw materials. Plus, pre-owned models save you money because used items cost less, less downtime is necessary for training and replacement parts are usually cheaper.

- Put a premium on prefabrication: Prefab construction minimizes waste since it’s easier to control material usage when building components off-site in a factory-controlled environment. More importantly, construction modules lend themselves to deconstruction, simplifying dismantling and material recovery for reuse or resale.

- Emit Less

Decarbonize your operations at every turn. Switching from diesel to electric is one of the best ways to do so. Powering your assets with nothing but electricity eliminates air and noise pollution on-site.

Running on electricity doesn’t automatically translate to fewer greenhouse gas emissions. In 2023, fossil fuels produced 60% of the electricity generated in the United States. The nation’s power mix will be cleaner once green hydrogen becomes ubiquitous, so operating electric construction assets will be even more eco-friendly in the future.

If upgrading to electric equipment doesn’t make sense for you, adopting renewable diesel is the next best thing. This alternative fuel is chemically identical to fossil-derived diesel, so you can use it on your existing assets without modifying anything. Renewable diesel releases fewer climate change gasses because it burns cleaner.

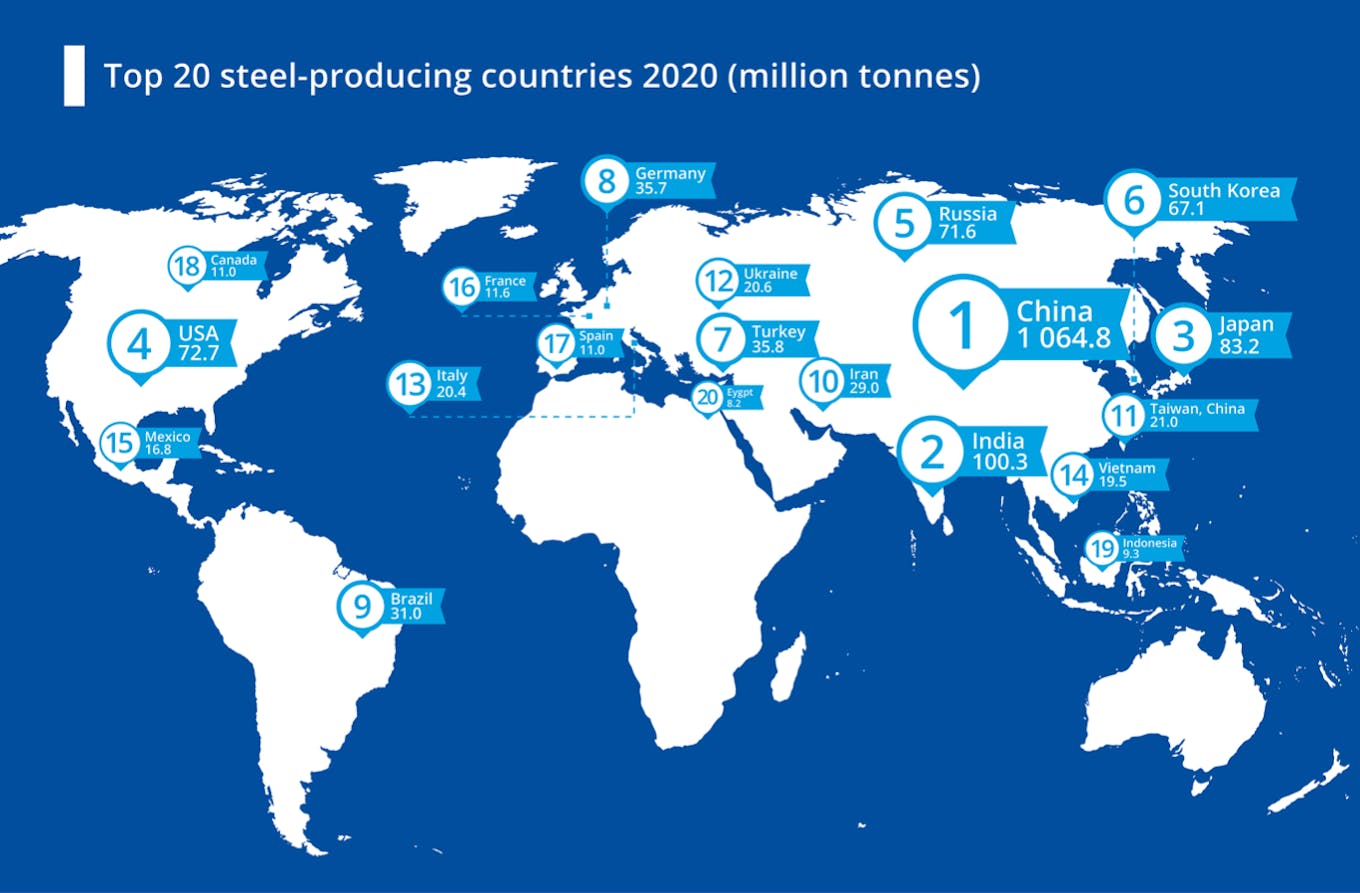

Furthermore, localize your supply chain. Ships are responsible for 3% of all greenhouse gasses linked to human activities globally. Ordering materials from overseas will increase your construction firm’s carbon footprint, but transporting domestically sourced materials involves fewer emissions. It’s also logically simple because they cover less ground and avoid Customs and Border Protection. As a bonus, you enjoy shorter lead times.

Make it a mission to have a lean mindset. A lean construction philosophy aims to cut waste at every chance, minimizing idle time and redundant processes that drive up greenhouse gas emissions.

- Look Ahead

Sustainability isn’t an objective — it’s a purpose. It’s a never-ending pursuit, so always seek new ways to run your construction firm in an environmentally friendly way.

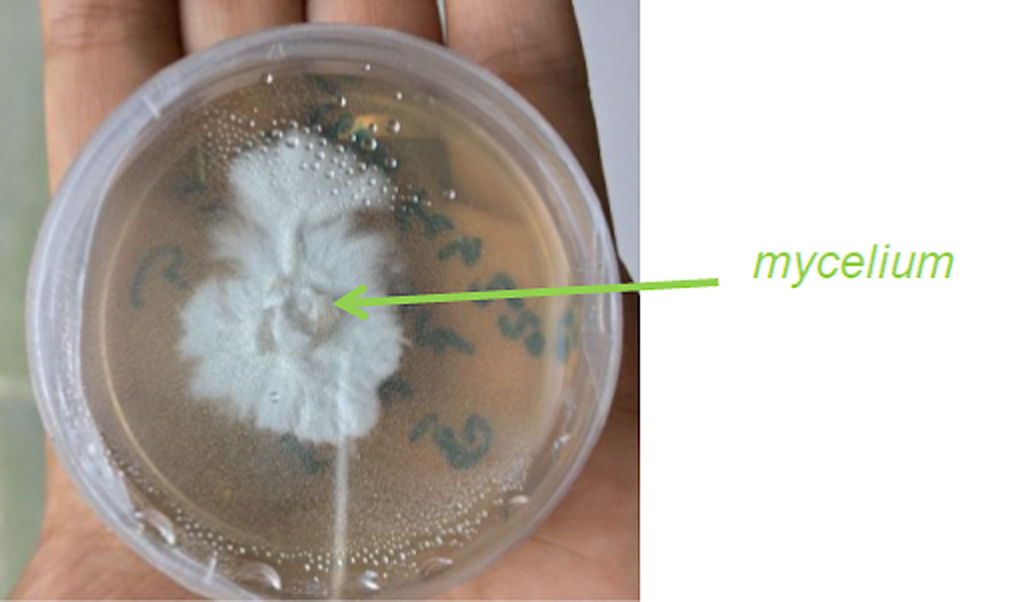

Lack of knowledge about emerging technologies is among the limiting factors in innovating. Curiosity is the antidote to ignorance, so keep up with the hottest trends in eco-building. Transparent wood, superabsorbent hydrogel, luminescent cement, 3D-printed soil structures, biodegradable polyurethane foam and plasma rock are some of the most promising innovations.

Most promising eco-friendly construction solutions take a lot of development before becoming ready for sale — and only a few ultimately gain mainstream acceptance. Although many ingenious ideas don’t pan out, be ahead of the curve. Use them to inspire regenerative and climate-resilient building designs that positively impact the environment for decades.

Take Small Steps Toward Sustainability

These four strategies only scratch the surface of what you do to be a force for good in the sector’s sustainability transformation. Strive to be more eco-friendly as you grow and you’ll establish a solid reputation as a green construction business.

Source Happy Eco News