Mush-Rooms: Mycelium concrete (Myocrete) could revolutionize low-carbon building construction and provide another tool for building green.

A new paper published by the University of Newcastle has outlined a new method of creating a mycelium concrete construction material, with potentially far-reaching changes as a result.

The Need for Low-Carbon Building Materials

Concrete, by far, is the world’s most used building material. It is cheap, incredibly strong, and easy to manufacture. However, it carries costs elsewhere in our world.

The environmental impact of concrete manufacture, use, and transportation is incredibly high. Concrete production is responsible for 8% of all greenhouse gases worldwide, making it the second largest source of greenhouse gas emissions. Natural materials like mycelium concrete (myocrete) might be part of the answer.

Burning fossil fuels creates most of these greenhouse gases to heat the enormous kilns used to create concrete. As well as that, there are the negative effects of mining the sand and gravel required to create concrete, which disturbs the environment and destroys natural ecosystems.

There is also the fact that concrete production requires massive amounts of water, which puts a strain on communities and areas already in need.

There have been some developments to make concrete less environmentally damaging, such as improving the efficiency of kilns so they don’t require as much heat; however, by and large, concrete production and use have been disastrous for our world.

Nevertheless, new developments have been underway to replace this widely used building material, such as mass timber. However, a unique and potentially revolutionary new material could be just around the corner, and it’s something that you’re probably more used to seeing on your plate than in your buildings.

Mushrooms in Our Walls

Mycelium-based construction material research, including mycelium concrete, has been underway for several years, as the effects of concrete production have been well-documented for decades. However, so far, the ability to scale and use mycelium in construction has been limited by the available technology and methods.

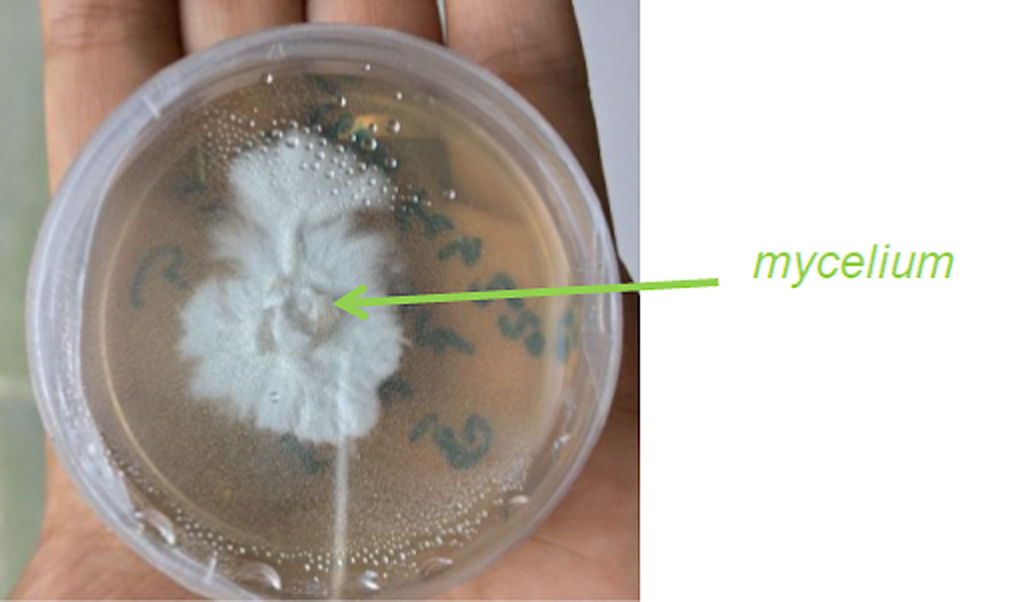

Currently, the method used in creating mycelium-derived construction materials is by filling a rigid mold with a mixture of mycelium and a food source such as grain for the mycelium. This method can produce rigid shapes, such as bricks, which can be used in construction.

However, there are limitations to the usability of these materials. For one, the strength required to compete with concrete isn’t there, and the rigid mold limits the variety of shapes and structures.

A new method created at the University of Newcastle, dubbed mycocrete (mycelium concrete), could completely change this and how construction has been done. The way mycocrete works is similar to past methods, with some distinctions.

One of them is in the mold that the paste is put into; where previous methods used rigid molds, mycocrete uses a permeable knitted mold that facilitates the growth of the mycelium by the amount of oxygen available. This flexible mold also allows the mycelium to grow in shapes that otherwise would be impossible with a rigid mold.

The process works by filling the knitted mold with a mixture of mycelium, paper powder, paper fiber clumps, water, glycerin, and xanthan gum. This is then hung up in a dark, warm, humid environment to facilitate the mycelium’s growth.

The result is a mycelium-based material significantly stronger than conventional mycelium bricks, notably much stronger than the material created with rigid molds. This is due to the amount of oxygen the mycelium has access to, given the mold’s permeability.

Myocrete is Still in the Early Stages, Though

However, despite the team’s promising results at Newcastle, myocrete mycelium concrete based buildings are still quite far off.

While continuing to develop the mycelium compound is still of major importance, the main obstacle is the fact that the factories and industries that work with the construction industry will need to be re-tooled for mycelium concrete along with new installation equipment being implemented.

Nonetheless, they have created some interesting prototypes, including the “BioKnit” project. This project was created to demonstrate the use of alternative materials in solving conventional construction design problems.

The team created BioKnit as one piece to limit weak spots inherent in joinery. Dr. Jane Scott, the author of the corresponding paper, said, “Our ambition is to transform the look, feel, and well-being of architectural spaces using mycelium concrete in combination with biobased materials such as wool, sawdust, and cellulose.”

With the priority being placed on reducing the environmental impact of construction, this new method could completely change the way we live and the spaces we live inside.

Source Happy Eco News