Fermentation has a long, rich history in food production, from beer and wine to yogurt and cheese, leavened bread and coffee, miso and tempeh, sauerkraut and kimchi, to name just a few of the tasty things we can consume thanks to a chemical process thought to date back to the Neolithic period. But if this 2017-founded Finnish startup, Solar Foods, has its way, fermentation could have a very special place in the future of human food too.

The industrial biotech startup is working on bringing a novel protein to market — one it says will offer a nutritious, sustainable alternative to animal-derived proteins. The product, a single-cell protein it’s branding Solein, is essentially an edible bacteria; a single-cell microbe grown using gas fermentation. Or, put another way, they’re harvesting edible calories from hydrogen-oxyidizing microbes.

“Technically it’s like a brewery,” explains CEO and co-founder Dr. Pasi Vainikka in an interview with TechCrunch. “Like fermentation technologies are. It’s not that strange [a process] — there is this one difference, which is the feedstock.”

The production of Solein requires just a handful of ‘ingredients’: Air, water and energy (electricity) — which means there’s no need for vast tracts of agricultural land to be given out to making this future foodstuff. It could be produced in factories located in remote areas or inside cities and urban centers.

Nor indeed are other foods needed to feed it to create an adequate yield, as is the case with rearing livestock for human consumption. So the promise looks immense. (As Vainikka argues: “Land use and energy use are the two main problems of human kind — and the rest follows from these two.)

Nutritionally speaking, Solein resembles some existing foodstuffs — sitting between dried meat, dried carrot or dried soy in terms of the blend of vitamins, amino acids, proteins (overall, it’s 65% protein), per Vainikka. “So it’s very familiar but it’s a bit [of a] new combination,” he suggests, adding: “The taste is very mild, very neutral.” (A mild taste may not sound especially scintillating for the tastebuds but it means it’s easy to include as an ingredient in a wide range of foods without the need for a strong flavor to be masked.)

While Solar Foods has essentially discovered a new species through its fermentation process, the microbe itself obviously hasn’t just appeared on planet Earth — and is likely very ancient; perhaps even hundreds of millions of years old. So there’s a fascinating blend of old and new coming together in the startup’s bioreactor.

Why is finding new forms of protein important? The problem Solar Foods is aiming to tackle is that the environmental costs of livestock-based meat production are indisputably massive — whether you’re talking unsustainable land and water use; climate-heating emissions and pollution; or animal welfare concerns. But what if you could produce billions of nutritious meals without the need to deforest huge swathes of land and slaughter masses of livestock to produce the food? What if humanity could feed itself and stop consuming the planet in the process?

That’s the promise and the core differentiator that Solar Foods claims vs. animal-derived proteins.

If you compare Solein to the growing gaggle of plant-based meat alternatives, they do still rely upon land being farmed to produce the necessary plants — whether soy or pea or oat, etc. — that form the basis of their products. Although they need far less land than meat production requires so the environment upside is still very real. But Solar Foods sees itself blending into this competitive mix — selling Solein to companies producing plant-based foods as another ingredient they can use to cook up nutritious, environmentally friendly meals.

“Cereals, vegetables, fruits, herbs aren’t going anywhere,” says Vainikka, discussing how Solein might fit into an evolved food production system. “So if we go back to the original problem — 80% of all the problems that have to do with food, whether it’s loss of natural habitat or forest loss or whatever, has to do with the industrialized animal production … So actually Solein could solve 80% of the problem but 20% of the calories because mostly we are, on a calorie basis, eating carbohydrates.”

And if you’re excited about the promise of lab-grown meat — which is also seeking to delink protein production from land use — Vainikka says the startup is supportive of such efforts since, once again, it’s spying potential customers as he says cultivated/lab-grown meat producers could use Solein to feed the cell cultures they’re using to grow slaughter-free steaks.

So use cases for Solar Foods’ edible bacteria look broad, provided people are willing to eat it (or have it fed to something in their food chain). Conceivably it could even be used as a feedstock for livestock — although the startup’s messaging is focused on the need to transform a broken food system and enter “the era of sustainable food production,” as its website puts it.

It is also working on developing a closed-loop system in which the sole byproduct of its production process — water containing bits of the Solein protein — would be continuously recycled back into production of more of the foodstuff. And if it can pull that off, the edible bacteria could potentially function as a life support system for humans on space missions where the timescales are too long for astronauts to rely on food supplies brought with them from Earth (such as, for example, a mission to Mars).

“The specific thing that we think is different in what we’re doing — compared to anything else on the market today — is that we don’t use any agriculture in the foods,” Vainikka tells TechCrunch. “Electricity and carbon dioxide are the main ingredients — instead of sunlight and carbohydrates or oils. So that’s the fundamental point where the disconnection of food production from agriculture happens.

“That’s our thing. And the reason to do that is once you can delink the connection between use of land and land-use impacts and food production then basically all the environmental benefits fall on your lap that there can be in relation to food production.”

Down here on Earth, being able to unhitch food production from the vagaries of seasonal weather and other factors that can have major impacts on agricultural yields — such as pests, natural disasters, issues with supply chains specific to farming and so on — is another touted advantage for Solar Foods’ approach. “Security of supply … consistency and quality,” says Vainikka, checking off some of the added advantages he says the edible protein offers vs. traditional farming, i.e., on top of the massive heap of land-delinking-based environmental gains which could — for example — support a mass reforestation of farm land, promoting biodiversity and fighting global warming since trees suck up CO2.

Europe’s energy crisis bites

Solein looks like a no-brainer on the environmental front. But one key component of its production — energy, i.e., electricity — is facing supply issues of its own in Europe at present in the wake of Russia’s invasion of Ukraine. (Russia being a major but unreliable supplier of gas to Europe.)

Solar Foods’ long-term bet is on energy production costs being brought down (or, well, stabilized) by widespread access to cheap renewables — such as wind and hydro energy in the north of Europe and solar in the sunny south. Thing is, for now, the European energy markets are typically structured so that the wholesale price of energy is linked to the cost of the most expensive type of energy (fossil fuel derived) despite there already being a fair amount of renewable energy available which is far cheaper to produce. (Hence why if the price of gas goes up the wholesale price of energy rises, and the bill payer must pay more even if their energy supplier sources their energy from cheaper to produce renewable sources.)

Since the Ukraine war started, Europe has been facing an exacerbated supply vs. demand issue. And over the past several months it’s been hard for Europeans to escape energy price spikes as their governments have sought to reduce reliance on Russian gas imports — shrinking energy supply options and helping keep war-spiked wholesale prices high.

The coming winter looks very grim, with Russia recently electing to entirely shutter gas exports via its Nord Stream pipeline to Germany in what looks like an attempt to weaken Western support for the pro-Ukraine sanctions. So energy supply in Europe has become a weapon of economic war.

It’s an incredibly volatile situation but one thing is clear: Europe’s ‘competitive’ marginal-cost-based energy markets are in desperate need of structural reform — to reflect the cheaper production costs of renewables and ensure consumers and businesses aren’t at the mercy of fossil fuel volatility and cripplingly high prices linked to Russian aggression.

But, in the meanwhile, with electricity being a key component of Solar Foods’ process, the startup is having to manage what Vainikka — who has a background in energy economics that he says allows him to understand where the markets are headed — refers to with classic Nordic understatement as “turbulence.”

He suggests Solar Foods may therefore need to wait out the current energy crisis before it’s able to scale commercial production of Solein in a way that’s economically viable — though it’s banking on Europe being able to find a way through to more stable electricity prices in the not too distant future. (In recent days, the Commission has said it will be coming with an emergency reform plan to curb energy prices — both in the short term and over the longer run, to ensure prices reflect cheaper renewables.)

“At the moment we shouldn’t make electricity supply agreements for our factory. We can’t be on the market today to make those agreements,” confirms Vainikka. “Because of this [energy price volatility] — it’s a fact. The second [thing] is we are quite happy that we are not fermenting natural gas — we are fermenting electricity. So we have an opportunity to make a good deal after turbulence.”

“We need to replace fossil fuels with electricity so we need a lot of new generation capacity which is also a problem in the market but we’re confident that this works,” he adds. “Unfortunately there is this turbulence now.”

Solar Foods is pressing on regardless of the current energy crisis.

It’s in the process of building its first factory — actually a demo facility, as a step on the road to future commercial scaling up of Solein production — at a cost of around €40 million, drawing on backing from a number of VC funds since 2017, over seed and Series A rounds, as well as raising debt financing (such as €15 million from Danske Bank Growth earlier this year).

The demo facility at least won’t have major energy requirements to run. (Although he says it’s still holding off on signing an energy supply contract for now.)

“We’ll manage the turbulence but of course it would be better for it not to continue too long,” says Vainikka. “We’re using this demo [facility] operated by one wind turbine to prove that this scales — but the real factories would be 100x larger in terms of energy use, 50x larger — and it would need rather 50 turbines to run a huge facility that will produce half a billion meals. Then you must get a good [energy supply] contract and if we were investing into that factory now it might be postponed because of the turbulence.”

Good food and food for good?

With the demo factory set to come on stream in 2023, Solar Foods’ hope is the first consumer product containing Solein will be on the market by the end of next year (or, failing that, in early 2024). Which global market will get the first commercial taste of the novel protein will depend on regulatory clearances.

Solar Foods has applied for clearance in multiple jurisdictions but can’t predict whether regulators in Europe or the U.S. or Asia will be first with approval, given variances in this process. (But Vainikka says it’s possible the first clearance could happen this year.)

What the first product for sale to consumers that contains Solein will be also isn’t yet clear.

Vainikka suggests a few possibilities — such as that it could be added to existing foods like breakfast cereals or vegan meals for fortification purposes (owing to its vitamin and mineral content, such as iron and B vitamins); or as a main ingredient in plant-based meat replacement products, replacing stuff like pea protein. Or he says it could be used as an egg replacement in pasta or pastry production. Or as a principle ingredient in ice cream or yogurt (or even to make a spreadable faux cheese).

“We leave the final formulation and product development for our customers so that we can empower them to renew categories,” he suggests. “And make having a food an act for good.”

“Frankly as a company we think that it might be a good idea to focus on what we master — which is this conversion-fermentation; producing this ingredient and so that it would have the functionalities needed for food products,” he continues, expanding on Solar Foods’ decision to stay in its biotech lane. “There are so many, so huge, or so experienced or so old [food] companies on the market who have already access to the consumer, all the experience regarding textures, product development regarding all kinds of plant-based ingredients and so on. So when we introduce Solein into the market you would not only need to get everything right, what we are doing and mastering now, but also the final product — of course taste and texture is decisive.”

“So that’s a heavy investment program that we’ve dived into,” he adds, emphasizing the still extensive range of requirements for developing a product that’s designed even to be an ingredient in processed foods that people eat.

“Nutrition must be there … then second is safety, then functionality, of course — how it works and forms texture — and then scaling and production technology; who has it, how does it work, is it scalable, and how does the supply chain work — so who’s really the gatekeeper? So this we are in the middle of now … A lot will happen in the next 12-16 months.”

While Solar Foods won’t be a food product maker itself it does have an R&D lab where it carries out culinary experiments with its product — and images on its website show a selection of demo foodstuffs, from chicken-style chunks served with pasta to soup, bread and a breakfast smoothies, all with a distinctive rich yellow hue.

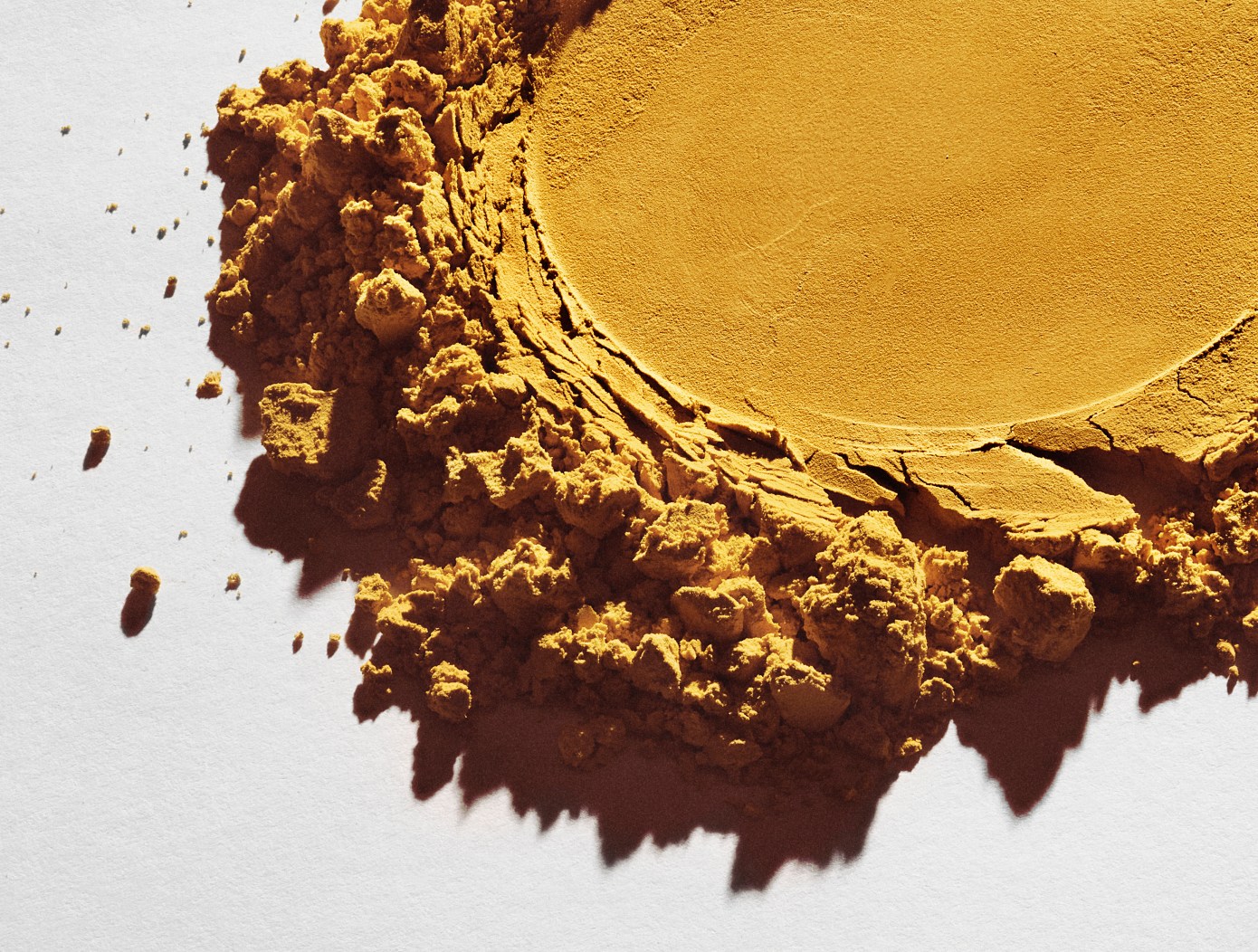

In its refined form — i.e., after it’s passed through Solar Foods’ electrolyzing and fermenting bioreactors and been dried — Solein takes the form of a yellow powder (the hue is down to betacarotene it naturally contains).

The strong color makes it looks a bit like a custom blend of turmeric and cumin. But tastewise it’s nothing like that strong. Per Vainikka, one expert taster who sampled it suggested it was akin to dried carrot. But whether you’re a fan of carrots is beside the point; he emphasizes that the taste is mild enough that it can be easily masked in whatever food product it was being incorporated into — just without the added nutrients going anywhere.

For example, in the sample case of adding Solein to pasta, Vainikka says it would — nutritionally speaking — be akin to eating, say, a plate of spaghetti bolognese with all the nourishment derived from an animal-based ingredient but without the need to have any minced meat on the plate. Which, well, might take some swallowing for those used to consuming traditional (and oftentimes culturally significant) recipes. (An Italian I described this meatless but nutritionally meat-like pasta dish to at a dinner party I attended recently was visibly shocked at the prospect and a second Italian she started to explain the concept to responded by suggesting we should focus on having fun eating the actual food on our plates instead of talking about, er, such high-concept stuff, so, well, there may be some acceptance humps in the short term.)

But as plant-based faux meats advance in taste and texture it’s easy to envisage creative food producers being able to whip up something that has a meat-like taste and texture and — thanks to the addition of Solein — is also imbued with similar levels of protein, iron and vitamins as actual meat. And that could be a strong selling point for consumers, especially with the current food fad for high-protein eating.

Other food ideas Solar Foods has been experimenting with in its labs are ‘cheese’ ball lollypops, mayonnaises and dressings, pancakes and plenty more besides.

Vainikka says he hopes the first commercial food to contain the ingredient won’t be a burger — since there are so many meat-alternative patty options out there already. But he suggests it could be a “meat-like bite” — something akin to a nugget — such as might be be served in an Asian hot pot or similar. “Then yogurt, ice cream, soup, bakery pastry application is something that might go first,” he postulates.

“You could imagine it could be a frozen food, fresh or even on the street kitchen of an Asian city,” he also suggests, saying the startup is keen to branch out and “appreciate different food cultures on the planet” — so it can “try to explain how Solein could be an ingredient in different kinds of dishes from the Asian hot pots to burger patties to soups or pastries or whatever.”

Food is of course not only cultural but individual tastes can be hugely personal — and/or political. So once Solein leaves Solar Foods’ factories and arrives in customers’ commercial kitchens that’s where all these localizing product and branding challenges will really kick in — as buyers will have to work on figuring out how best to blend it in with other taste and cultural considerations or indeed make its presence stick out loudly (at least on the packet) where shouting about sustainability benefits might be the best way to reap big sales in their particular target market.

One thing looks clear: The future of food won’t be dull — or even uniformly yellow hued. A full rainbow of possibilities for alternative eats are coming down the pipe — and the environmental challenges we face, as a species, demand we find the appetite to consume them.

Source Join Techcrunch+