Unilever has introduced new technology to create a paper-based detergent bottle. A prototype is being used for the OMO laundry brand (also known as Persil, Skip & Breeze) and will be introduced in Brazil in 2022.

The new bottles are made of sustainably sourced pulp and can be recycled in the paper waste stream. The inside of the bottle is sprayed with a proprietary coating that repels water, enabling the paper-based packaging to hold liquids.

Unilever wants to roll the paper-based bottles out across its European markets and is piloting the same technology for haircare bottles.

The bottles have been developed through the Pulpex consortium. Last year, drinks manufacturers Diageo and PepsiCo joined Unilever in the formation of Pulpex, with venture management firm Pilot Lite. The Pulpex consortium was set up to produce a variety of plastic-free, single-mould bottles that will be used across the major FMCG companies.

Diageo has already unveiled a plastic-free, paper-based spirits bottle, which will debut on the company’s Johnnie Walker range of Scotch Whisky this year.

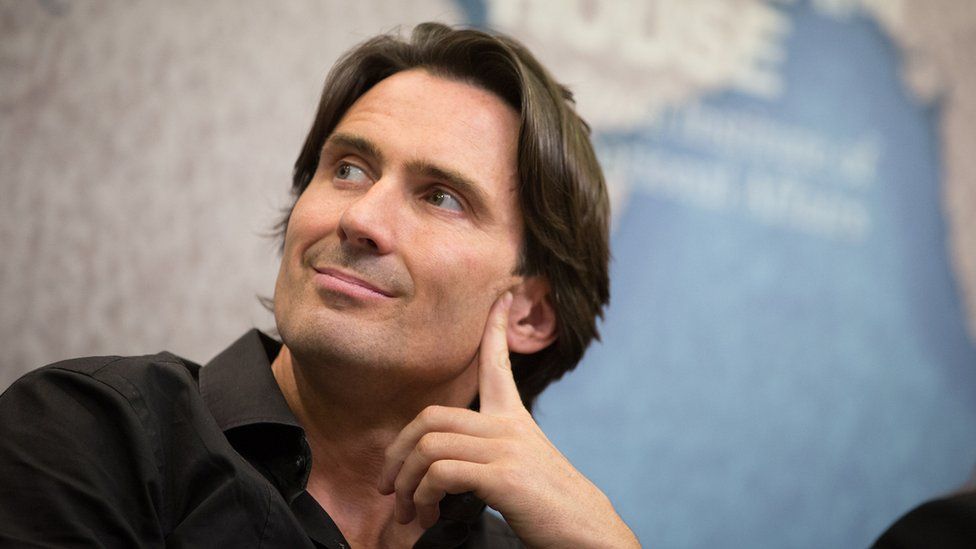

Unilever’s chief research and development officer, Richard Slater, said: “To tackle plastic waste, we need to completely rethink how we design and package products. This requires a drastic change that can only be achieved through industry-wide collaboration.

“Pulpex paper-based bottle technology is an exciting step in the right direction, and we are delighted to be working together to trial this innovation for our products. Innovating with alternative materials is a key part of our sustainable packaging strategy and will play an important role in our commitment to halve our use of virgin plastic materials by 2025.”

edie recently spoke with Slater to discuss how a focus on ‘better, less and no plastic’ is enabling the consumer goods giant to reduce its plastics footprint globally while improving the recyclability of packaging.

In 2019, Unilever, which owns iconic brands such as Dove, Cif and Magnum, set a target to halve its use of virgin plastic by 2025 by reducing plastic packaging by more than 100,000 tonnes, increasing the amount of recycled plastics it uses and collecting and processing more plastic packaging than it sells.

Unilever is the latest corporate to trial paper-based bottle prototypes.

The Coca-Cola Company – one of the biggest plastic producers in the food and beverage space – has confirmed plans to trial 2,000 paper-based bottles this year, to test the material’s viability as an alternative to single-use plastics.

The Coca-Cola Company has been working with other big-name companies, including Absolut, L’Oreal and Carlsberg, to develop the bottles. The designs are being shared through a collaborative company set up to facilitate this joint project, called The Paper Bottle Company (Paboco).

Fellow Paboco member Absolut confirmed plans for its first real-world trials of paper-based bottles. The alcoholic beverage giant has sold 2,000 of the bottles across its Swedish and UK markets since autumn 2020.

By Matt Mace

Source Edie