What is aluminum, and what is it used for?

Aluminum is a silvery-white, soft, nonmagnetic metal. It has good electrical and thermal conductivity and is used in many products, from cars and airplanes to packaging, foil and cans. It is a highly versatile metal, but many people don’t realize that it’s also one of the most carbon-intensive metals to produce.

Because it is used in so many diverse applications, the aluminum industry has a big environmental footprint. Aluminum production emits about 1% of global man-made greenhouse gas emissions. Most of these emissions come from using fossil fuels to make aluminum oxide (alumina), which is then reduced to aluminum metal in smelters.

The aluminum industry is working on ways to reduce its emissions. One promising technology is “carbon-free” or “green” aluminum production. This process uses renewable electricity – instead of fossil fuels – to produce alumina, which can then be turned into aluminum metal using existing smelting technology.

Several companies are already using or testing this technology, including Rio Tinto, Alcoa, Hydro and China’s Chalco. These companies are betting that carbon-free aluminum will be in high demand from industries and consumers who want to reduce their emissions footprints.

Why is aluminum production carbon-intensive?

There are two main reasons why aluminum production is so carbon-intensive. First, alumina, the raw material used to produce aluminum, is derived from bauxite ore, typically found in tropical regions. The process of mining and refining bauxite ore releases large amounts of carbon dioxide into the atmosphere.

Second, smelting alumina to produce aluminum metal emits significant amounts of carbon dioxide. Smelting is responsible for approximately two-thirds of the total emissions associated with aluminum production.

How will the industry decarbonize aluminum?

The most common method of producing aluminum involves the electrolysis of alumina in a high-carbon anode, which results in significant emissions of greenhouse gases. The industry is developing low-carbon technologies to reduce or eliminate these emissions.

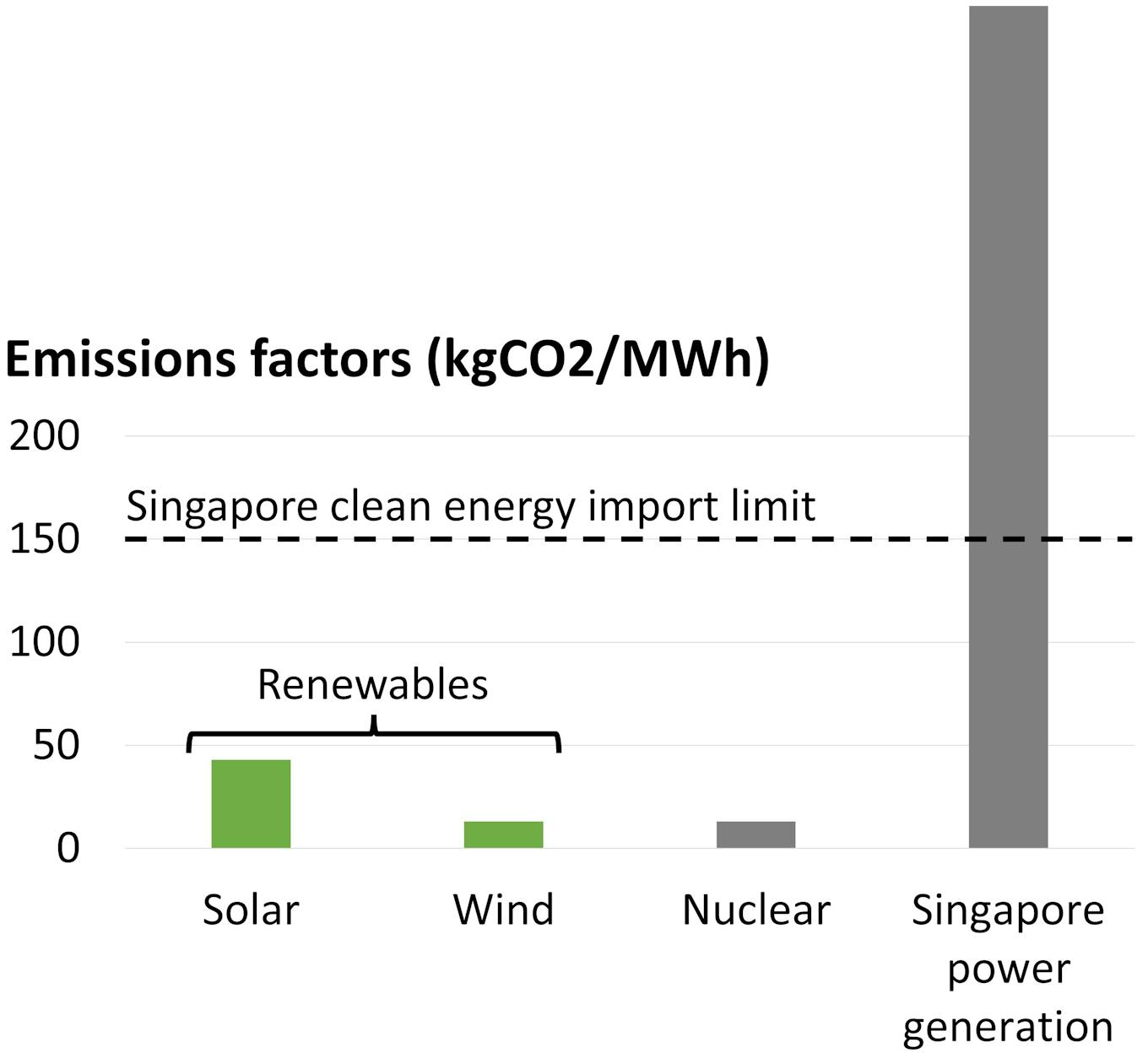

Another promising technology is using renewable energy to power the electrolysis process. This would significantly reduce the carbon footprint of aluminum production. Solar, wind, and hydroelectric power can all power these processes while significantly reducing or eliminating emissions.

Recycled aluminum requires less energy to process and emits far less carbon dioxide than virgin alumina.

Each of these options comes with its challenges, but the aluminum industry is committed to finding ways to reduce its environmental impact. For example, Rio Tinto is investing in research into new smelting technologies that could significantly reduce emissions. Alcoa is working on a project to power its operations with renewable energy from forest biomass waste.

Will the quality of low-carbon aluminum be lower?

Decarbonized aluminum is made using low-carbon methods, which results in a lower carbon footprint. However, some worry that this type of aluminum will be of lower quality than regular aluminum.

No evidence suggests that decarbonized aluminum is any less strong or durable than regular aluminum. In fact, it may even be of higher quality due to the extra attention to the manufacturing process and modern innovations in the process. Low-carbon methods often result in a cleaner and more pure product.

A study by the International Aluminum Institute found that, when using best practices, there was no significant difference in the quality of low-carbon aluminum and regular aluminum. The study found that, in some cases, low-carbon aluminum had superior properties.

This is because environmental regulations are becoming more stringent, forcing producers to innovate and find ways to reduce their carbon footprint without compromising on quality.

Source Happy Eco News